This article explores the significance and practical applications of the INA219 current and voltage Sensor module in monitoring Power supply systems. The INA219, a high-precision sensor, enables accurate measurement of voltage, current, and power in electrical circuits, making it invaluable in numerous fields such as electronics, renewable energy systems, and industrial applications. We will dive into the technology behind this sensor, its benefits, and real-world applications, as well as how it enhances power supply monitoring in various systems.

Introduction to the INA219 Sensor and Its Applications in Power Supply Monitoring

The ability to effectively monitor and manage power supply systems is vital across a wide array of applications, ranging from industrial power grids to small electronic projects. In particular, accurate monitoring of voltage, current, and power can prevent costly downtime, optimize energy efficiency, and ensure the longevity of electronic devices. This is where the INA219 current and voltage sensor module comes into play, providing a simple yet highly effective solution for power monitoring.

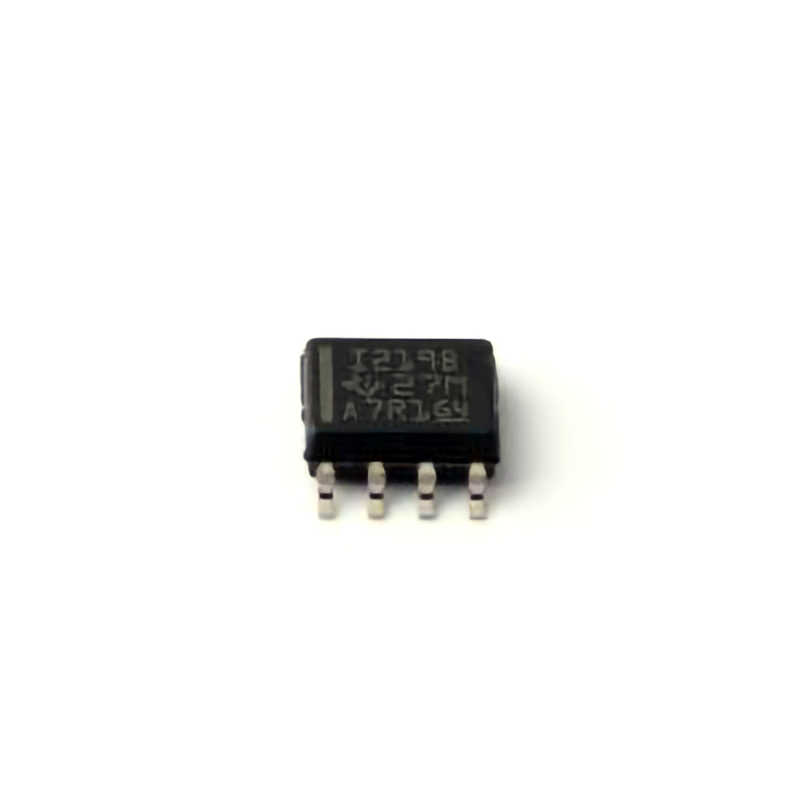

The INA219, designed by Texas Instruments, is an advanced sensor that allows engineers, makers, and hobbyists to measure current, voltage, and power with high precision. Using the I2C Communication protocol, the INA219 can easily integrate with a wide variety of microcontroller-based systems like Arduino, Raspberry Pi, and other embedded platforms. But what makes the INA219 stand out from other power monitoring solutions? Let’s dive into the technology behind the module, its features, and its core benefits.

1.1. Understanding the INA219 Sensor Module

The INA219 sensor is based on a shunt resistor, which is placed in series with the power supply circuit. This resistor acts as a measurement point for the current flowing through the circuit. By measuring the voltage drop across the shunt resistor, the INA219 can accurately calculate the current flowing in the circuit. Additionally, the sensor also measures the supply voltage and computes the power consumption of the system, providing real-time feedback on power usage.

Key specifications of the INA219 sensor include:

Voltage Measurement Range: 0 to 26V

Current Measurement Range: 0 to 3.2A (depends on the value of the shunt resistor used)

Power Measurement: Accurate power measurement (up to 75W)

Precision: High-precision, with an accuracy of up to 1%

Communication interface : I2C (inter-integrated circuit) for easy integration into microcontroller systems

Low Power Consumption: Suitable for low-power and battery-powered applications

The INA219 uses a 16-bit analog-to-digital converter (ADC) for voltage and current measurements, allowing it to provide high-resolution readings. It also offers programmable calibration, which can be adjusted to suit the specifics of the system being monitored.

1.2. Benefits of Using INA219 for Power Supply Monitoring

The primary advantage of the INA219 is its ability to provide real-time data on the voltage, current, and power usage of a circuit. In power supply monitoring, this data is essential for several reasons:

Efficiency Optimization: By tracking the power consumption of individual components, the INA219 helps in identifying energy inefficiencies. For example, in a solar power system, monitoring the power output of the system can help in understanding how much energy is being generated and consumed, allowing for adjustments to optimize overall efficiency.

Overcurrent Protection: Many power supply systems are prone to damage if they experience overcurrent conditions. The INA219 can be used to monitor current levels, triggering alarms or shutdowns if the current exceeds safe limits, thereby protecting the system from damage.

Predictive Maintenance: In industrial and commercial power supply systems, the INA219 can assist in predictive maintenance by providing continuous monitoring of power parameters. Sudden changes in voltage or current might indicate potential faults, enabling early detection and reducing the risk of system failures.

Data Logging and Analysis: The sensor's I2C interface makes it easy to connect the INA219 to Microcontrollers that can log data over time. This can be particularly useful in applications where long-term power usage patterns need to be analyzed for research or operational optimization.

Compact and Cost-Effective: The INA219 module is relatively inexpensive and compact, making it suitable for both small-scale DIY projects and large-scale industrial applications. Its affordability ensures that precise power monitoring can be implemented in scenarios that otherwise would be too costly.

1.3. Practical Applications of INA219 in Power Supply Systems

The versatility of the INA219 makes it suitable for a wide range of applications, from home automation to renewable energy monitoring. Let’s explore some real-world use cases where the INA219 module is enhancing power supply monitoring capabilities.

Solar Power Systems: In solar energy systems, especially off-grid setups, efficient power generation and consumption tracking are critical. The INA219 can measure the current and voltage output from the solar panels, batteries, and inverters, allowing operators to track system performance, optimize energy storage, and detect faults before they result in system downtime.

Battery-Powered Devices: For battery-operated devices, the INA219 can track battery voltage, current drain, and overall power usage. This helps in ensuring that the device is operating efficiently and allows users to take preventive measures to avoid battery depletion or damage.

Uninterruptible Power Supplies (UPS): Monitoring power in a UPS system is vital for ensuring reliable backup during power outages. The INA219 can measure the voltage and current output from the UPS and provide real-time feedback, helping to prevent potential power disruptions and extend the lifespan of the battery.

Electric Vehicles (EVs): The INA219 can also be employed in electric vehicle power systems to monitor the current and voltage levels from the battery and electric motor, providing feedback on energy consumption. This helps in maximizing the range and efficiency of the vehicle.

Power Supply in Industrial Automation: In industrial environments, maintaining stable power supplies is crucial for the operation of machines, Sensors , and control systems. Using INA219 modules to monitor voltage and current across different equipment can help in identifying power anomalies, ensuring continuous operation, and preventing unexpected breakdowns.

Advanced Usage, Integration, and Future Trends in Power Supply Monitoring

While Part 1 highlighted the basic applications and advantages of the INA219 sensor module in power supply monitoring, there are many advanced integration possibilities and trends worth exploring. As technology evolves, power supply monitoring continues to play a critical role in various fields, and sensors like the INA219 will only become more valuable in enabling smarter, more efficient systems.

2.1. Integrating INA219 with IoT Systems

The Internet of Things (IoT) is revolutionizing how devices communicate and interact with each other, and power supply monitoring is no exception. By integrating the INA219 sensor into IoT systems, real-time data on power usage can be transmitted to cloud platforms or local servers for remote monitoring and analysis.

For instance, smart homes can utilize INA219 sensors to track the power consumption of appliances, lighting systems, and HVAC units. With IoT integration, users can access power usage data via mobile apps or web dashboards, allowing them to make informed decisions about energy use and reduce their electricity bills.

In industrial settings, the INA219 can be incorporated into larger IoT networks to track power consumption across different machines and systems. This data can then be used for predictive maintenance, energy optimization, and overall system health monitoring.

2.2. Using INA219 with Microcontroller Platforms

Microcontrollers such as Arduino and Raspberry Pi are widely used in power supply monitoring projects due to their ease of use and versatility. The INA219 sensor integrates seamlessly with these platforms, enabling users to design custom monitoring systems.

For instance, Arduino enthusiasts can use the INA219 sensor to build DIY power meters, battery monitors, or solar power monitoring systems. The data from the INA219 can be processed by the Arduino, which can then take actions based on predefined conditions, such as activating a fan when the temperature exceeds a certain threshold or sending an alert if the current exceeds safe levels.

Raspberry Pi, with its more powerful processing capabilities, can handle more complex applications, such as logging power consumption data over extended periods, analyzing trends, and even controlling other devices based on power usage. This opens up a wide range of possibilities for creating sophisticated power supply monitoring solutions.

2.3. Future Trends and Innovations

As we move into an increasingly connected and energy-conscious world, the role of power supply monitoring technologies will continue to evolve. The integration of sensors like the INA219 into smart systems is only the beginning. Future trends include:

Energy Management Systems (EMS): The integration of INA219 sensors into larger energy management systems will allow for real-time optimization of energy consumption across homes, businesses, and industries. These systems will not only monitor power usage but will also suggest optimizations based on data analysis.

Integration with Artificial Intelligence (AI): AI algorithms could be used to predict power demand based on historical data collected by INA219 sensors, allowing systems to automatically adjust settings to optimize energy use. For example, AI could predict when a solar panel is likely to generate maximum power and adjust the power flow accordingly.

Wireless Power Monitoring: In the future, sensors like the INA219 may be combined with wireless technologies such as Zigbee, LoRa, or Wi-Fi, enabling remote monitoring without the need for physical wiring. This would be particularly useful in hard-to-reach locations or large-scale power systems where cabling is impractical.

Enhanced Sensors for Higher Power Applications: While the INA219 is suitable for many low- to mid-power applications, future iterations of this sensor or similar devices may be developed to handle higher voltage and current ranges. This will open the door for broader use in industrial power grids, electric vehicles, and high-powered electronics.

Conclusion

The INA219 current and voltage sensor module is an incredibly versatile and powerful tool for monitoring power supply systems. Whether it’s optimizing energy efficiency in solar power systems, providing real-time data in battery-powered devices, or ensuring stability in industrial power supplies, this sensor proves to be an essential asset for both professionals and hobbyists alike.

As the demand for energy-efficient and connected systems continues to grow, the importance of reliable power supply monitoring will only increase. The INA219’s ability to offer high precision, ease of integration, and cost-effectiveness makes it a key component in the development of smarter, more efficient energy systems across a wide range of applications. The future of power monitoring is bright, and technologies like the INA219 are leading the way.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.