In the modern era of increasingly sophisticated electronic devices, Power Management has become a critical aspect of design. The TPS54620RHLR , a high-efficiency Power Management module , stands out as a robust solution for optimizing energy use, improving overall system performance, and minimizing heat dissipation. This article delves into the technical features, optimization strategies, and applications of the TPS54620RHLR in high-efficiency power management modules, exploring how it helps engineers meet the stringent demands of today’s power-hungry technologies.

TPS54620RHLR, power management, efficiency, optimization, DC-DC converter, high-efficiency power modules, energy optimization, electronics design, power solutions, Thermal Management , power integrity

Introduction to Power Management Optimization with TPS54620RHLR

In the world of electronics, one of the foremost challenges is how to provide reliable power while maintaining high energy efficiency. Whether in consumer electronics, Telecom munications, or industrial machinery, every device relies on optimized power delivery systems to ensure reliability, minimize energy loss, and prevent overheating. The TPS54620RHLR, a state-of-the-art DC-DC converter, offers an excellent solution for high-efficiency power management modules, meeting the rising demands of modern electronics for more power-efficient systems.

What is TPS54620RHLR?

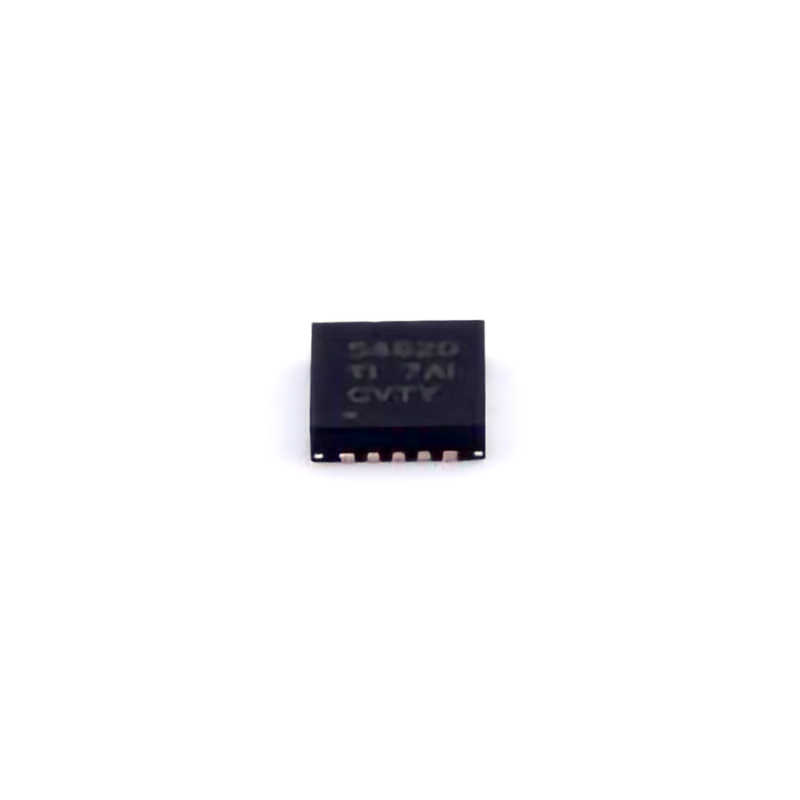

The TPS54620RHLR is a high-performance, step-down DC-DC converter from Texas Instruments, designed to provide highly efficient power regulation. It belongs to the family of synchronous buck converters, making it ideal for systems that need to convert a higher input voltage to a stable, lower output voltage. This module supports a wide input voltage range of 4.5V to 60V, making it versatile for a variety of applications, including embedded systems, automotive electronics, industrial applications, and communication devices.

Key features of the TPS54620RHLR include:

Efficiency up to 95%: The TPS54620RHLR operates with minimal power loss, reducing the amount of heat generated and thereby improving system reliability and lifespan.

High Output Power: Capable of supplying up to 20A of continuous output current, it’s perfect for powering demanding loads in high-performance systems.

Wide Input Voltage Range: Its wide input range ensures compatibility with various power sources, offering flexibility in diverse environments.

The primary benefit of this power module is its ability to optimize the energy conversion process, making it a favorite for designers who need to balance power integrity with minimal energy waste.

The Importance of Efficiency in Power Management

As electronics continue to evolve, the need for efficient power management systems has become more critical. Devices are becoming more complex, with increasingly stringent requirements on size, power consumption, and heat dissipation. Engineers must design power solutions that not only supply adequate power but do so without generating excessive heat or consuming excessive amounts of energy.

High efficiency is essential for:

Maximizing Battery Life: For battery-operated devices, whether mobile phones or autonomous machines, optimizing power usage extends battery life, ensuring that devices can operate longer on a single charge.

Reducing Heat Generation: Excessive heat can lead to system failures and reduced longevity of electronic components. Efficient power conversion reduces this heat generation.

Improving Energy Cost Efficiency: In commercial applications, lower energy consumption translates to reduced operational costs, making energy-efficient systems attractive in industrial and telecommunications sectors.

Compliance with Regulations: Many industries are subject to regulations that require energy-efficient designs. The TPS54620RHLR helps meet these standards by ensuring optimal power use.

The TPS54620RHLR stands out by addressing these challenges head-on, offering an elegant solution for those seeking to enhance their power management systems without compromising on performance.

Key Features Driving Optimization

The optimization of power management systems is crucial for balancing performance with power efficiency. The TPS54620RHLR achieves this through several key features:

Synchronous Rectification: This technique improves efficiency by using both an upper MOSFET and a lower MOSFET in the switching process. The synchronous rectification reduces conduction losses, contributing to higher efficiency and lower heat generation. This is especially useful in applications where power consumption is critical.

Advanced Control Architecture: The TPS54620RHLR employs a peak current mode control architecture that ensures fast response to load changes and improves overall stability. This control mechanism helps the module maintain stable output voltage across varying loads and input conditions.

Programmable Switching Frequency: By adjusting the switching frequency, designers can optimize the balance between efficiency and the size of external components. In systems where space is a pr EMI um, increasing the switching frequency can reduce the size of the passive components, such as inductors and capacitor s, without sacrificing efficiency.

Low Quiescent Current: The TPS54620RHLR has a low quiescent current, meaning it consumes less power in standby or idle modes. This is particularly useful in applications where low power consumption during non-operating periods is essential, such as in battery-powered devices.

Applications in High-Efficiency Power Management

The versatility of the TPS54620RHLR makes it suitable for a wide range of applications where efficiency and reliability are crucial. Some of the most notable use cases include:

Industrial Automation: In industrial environments, maintaining power efficiency while ensuring equipment runs smoothly is paramount. The TPS54620RHLR is ideal for powering control systems, sensors, and other industrial equipment that require stable and efficient power delivery.

Telecommunications: In telecom systems, high power density and efficiency are vital for optimizing the performance of base stations and communication modules. The TPS54620RHLR’s ability to deliver up to 20A of current makes it perfect for these applications.

Automotive Electronics: The automotive industry increasingly relies on advanced electronics for everything from infotainment systems to safety features. Power management is critical in automotive electronics, and the TPS54620RHLR ensures that these systems remain both energy-efficient and reliable.

Consumer Electronics: Modern consumer electronics, such as smartphones, tablets, and laptops, require power management solutions that optimize battery life and reduce energy consumption. The TPS54620RHLR’s high efficiency and small form factor make it an excellent choice for these devices.

Conclusion of Part 1

In summary, the TPS54620RHLR is a highly versatile and efficient DC-DC converter that excels in optimizing power management across a wide range of applications. By delivering exceptional efficiency, minimizing heat generation, and offering flexible design options, this module helps engineers meet the rigorous demands of today’s electronic systems. In Part 2, we will explore the optimization techniques in greater detail, looking at the practical steps engineers can take to achieve the best performance from the TPS54620RHLR in real-world applications.

Advanced Optimization Techniques and Practical Design Strategies

In the first part of this article, we introduced the TPS54620RHLR and its impressive performance capabilities for high-efficiency power management. Now, we’ll delve into the more intricate design considerations and optimization techniques that engineers can use to fully leverage the potential of this power management module. Optimizing the use of the TPS54620RHLR involves careful attention to several key factors, including thermal management, component selection, and system integration.

1. Thermal Management Optimization

Efficient thermal management is crucial in ensuring the long-term reliability and performance of power modules. While the TPS54620RHLR is designed to operate with high efficiency and low heat generation, it is still essential to manage the heat produced by the module, especially in high-power applications.

Heat Dissipation Strategies:

Use of Heat Sinks: In high-current applications where power loss might increase, adding external heat sinks to the TPS54620RHLR can significantly improve thermal dissipation. Proper heat sink selection, considering factors such as thermal conductivity and surface area, is key to managing system temperatures.

PCB Design for Heat Distribution: The design of the printed circuit board (PCB) plays a pivotal role in heat dissipation. Designers should route high-current traces with a wide trace width to minimize resistive losses and reduce localized heating. Additionally, adding thermal vias and copper pours can help spread heat across the PCB, improving overall thermal management.

Ambient Temperature Considerations: The operating environment should also be considered when designing for thermal efficiency. Ensuring adequate airflow around the power module and selecting components rated for the anticipated ambient temperature range can help prevent thermal throttling and failure.

2. Capacitor and Inductor Selection for Enhanced Efficiency

The external components used in the power supply, such as Capacitors and inductors, are vital to achieving optimal performance from the TPS54620RHLR. Selecting the right components is essential for minimizing losses and ensuring smooth, reliable operation.

Choosing the Right Inductor:

Inductor Quality: Choosing an inductor with low core losses and low resistance can significantly improve the efficiency of the power module. Ferrite-core inductors, for instance, tend to perform better at high frequencies, minimizing energy losses and improving system efficiency.

Inductance Value: The inductance value directly influences the performance of the power supply. A higher inductance value results in lower ripple currents, but it also requires a larger inductor, which could increase system size. Thus, optimizing this tradeoff is essential for a well-balanced design.

Capacitor Selection:

Low ESR Capacitors: Choosing capacitors with low equivalent series resistance (ESR) can significantly improve the transient response and stability of the power supply. This is particularly important in applications where the system undergoes frequent load changes.

Capacitor Voltage Rating: The voltage rating of the capacitors should always exceed the output voltage to ensure reliability and prevent premature failure. Designers should also consider the temperature stability of the capacitors, particularly in environments where temperature variations are significant.

3. Control Loop and Compensation Network Optimization

The TPS54620RHLR employs a peak current mode control architecture, which is highly effective for maintaining stability under varying load conditions. However, to ensure optimal performance, engineers must design an appropriate compensation network to achieve the best balance between stability and transient response.

Optimizing the Feedback Loop:

The feedback loop should be carefully designed to avoid instability and excessive noise. This involves selecting the right compensation components, such as resistors and capacitors, to tune the control loop for the specific application.

Engineers should aim for a tradeoff between fast transient response (to minimize voltage dips during load steps) and a stable, noise-free output. Proper loop compensation ensures the module responds quickly to changes while maintaining output voltage within acceptable limits.

4. System Integration and Layout Considerations

System integration is another critical aspect of optimizing the performance of the TPS54620RHLR. The layout of the entire power supply circuit, including the placement of components and routing of traces, can have a significant impact on efficiency and stability.

Key Layout Guidelines:

Minimizing EMI: Proper layout can help reduce electromagnetic interference (EMI) in the system. Keep high-current traces short and thick, and place decoupling capacitors as close as possible to the power module’s input and output pins.

Ground Plane Design: Use a solid, uninterrupted ground plane to reduce noise and ensure stable operation. Keep the power and signal grounds separate to minimize the risk of ground loops that could affect the performance of the system.

Conclusion of Part 2

Optimizing the TPS54620RHLR in power management modules requires a holistic approach, involving careful component selection, thermal management, feedback loop design, and system integration. By considering these factors and applying advanced optimization techniques, engineers can ensure that the TPS54620RHLR delivers the best possible performance in a wide range of applications. Whether for industrial automation, telecommunications, automotive electronics, or consumer devices, the TPS54620RHLR remains a top choice for high-efficiency power management solutions, enabling efficient, reliable, and scalable designs.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.