The MBR0520LT1G is a popular Schottky Diode used in a variety of applications. However, like any electronic component, it can experience issues that affect its performance. In this article, we will explore common troubleshooting scenarios and provide solutions to ensure the MBR0520LT1G continues to function at its best.

MBR0520LT1G, Schottky diode, troubleshooting, electronic components, circuit failure, electrical issues, diode performance, Schottky diode repair, MBR0520LT1G solutions, electronic troubleshooting

Understanding the MBR0520LT1G and Identifying Common Issues

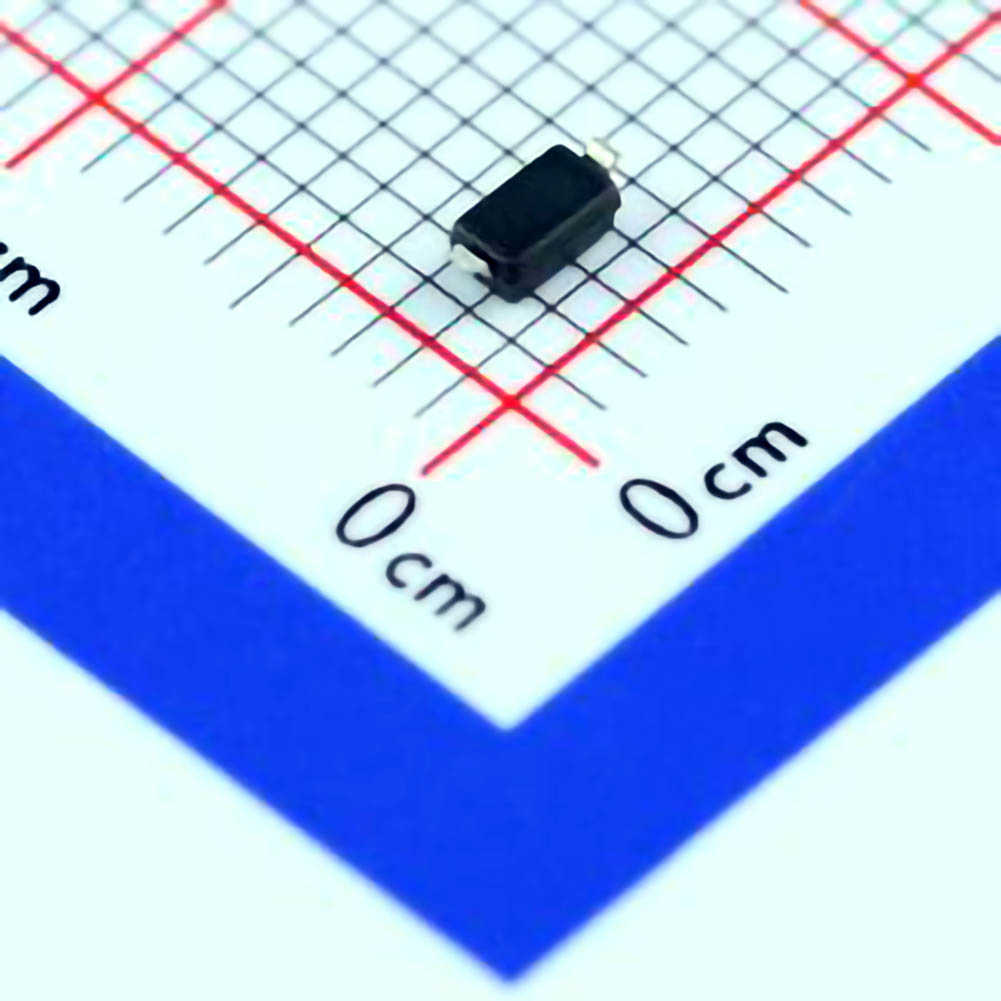

The MBR0520LT1G is a Schottky diode known for its low forward voltage drop and fast switching characteristics. It is commonly used in power rectification, voltage regulation, and protection circuits across a wide range of electronic applications. However, even though it is a reliable component, users may encounter various issues during its lifecycle. Understanding the potential causes of these problems is crucial for effective troubleshooting.

1.1 Recognizing the Symptoms of a Faulty MBR0520LT1G

Before diving into the specific solutions, it is important to first identify when your MBR0520LT1G might be malfunctioning. Common symptoms of a faulty diode can include:

Circuit not powering up or responding: If the diode is part of a power supply or regulation circuit, a failure may cause the entire system to stop functioning.

Excessive heating: Diodes that overheat often indicate an issue with the electrical current, such as a short circuit or incorrect voltage levels.

Unusual voltage drops: If you notice voltage drops that are too large for the specific application, the MBR0520LT1G could be damaged or performing poorly.

High reverse leakage current: Schottky diodes, such as the MBR0520LT1G, have low reverse leakage currents, but a faulty diode may exhibit unusually high leakage current, causing inefficiency.

If any of these symptoms occur, it’s time to investigate further.

1.2 Possible Causes of MBR0520LT1G Failures

Several factors can lead to the failure of the MBR0520LT1G diode. Here are some of the most common causes:

Overcurrent and Overvoltage Conditions: The MBR0520LT1G is rated for a maximum reverse voltage of 20V. If the circuit applies voltage above this threshold, the diode may fail due to breakdown.

Thermal Overload: Schottky diodes are sensitive to temperature, and excessive heat can quickly degrade their performance. Inadequate heat dissipation can cause the diode to overheat and fail.

Incorrect Polarity: While Schottky diodes are relatively tolerant of reverse polarity, using them in the wrong direction can cause them to conduct in reverse, leading to a failure.

Electrostatic Discharge (ESD): Schottky diodes, like the MBR0520LT1G, are vulnerable to ESD. Even small static charges can damage internal components and result in malfunction.

Aging or Mechanical Damage: Over time, repeated stress, exposure to high currents, or physical damage can cause the diode to degrade.

1.3 How to Test the MBR0520LT1G for Faults

If you suspect that your MBR0520LT1G is faulty, here’s how to check its condition:

Visual Inspection: First, inspect the diode visually for any signs of damage, such as discoloration, cracks, or burn marks. If you notice any, it’s likely the diode needs to be replaced.

Multimeter Testing: Use a digital multimeter to check the forward voltage drop across the diode. A healthy Schottky diode like the MBR0520LT1G will have a forward voltage drop typically between 0.2V and 0.45V, depending on the current. If the measurement is significantly outside this range, the diode may be faulty.

Reverse Leakage Current: Test for reverse leakage current by applying a small reverse bias (such as 5V) and measuring the current. A high reverse leakage current (above a few microamps) could indicate a damaged diode.

Thermal Imaging: Use a thermal camera or IR thermometer to identify any hot spots on the diode during operation. Excessive heating could signal a malfunction or overcurrent situation.

Solutions for MBR0520LT1G Issues and Preventative Measures

Once the problem is identified, the next step is to apply effective solutions. Below are some troubleshooting solutions for the most common issues that users encounter with the MBR0520LT1G.

2.1 Solution for Overcurrent and Overvoltage Conditions

If your MBR0520LT1G is failing due to overcurrent or overvoltage, here are the steps you can take:

Use Proper Circuit Protection : To prevent overcurrent or overvoltage conditions, use fuses, surge protectors, or voltage clamping devices in your circuit. A fuse should be rated slightly above the normal operating current to prevent excessive current from reaching the diode.

Select Appropriate Diodes: When designing circuits, ensure that the maximum reverse voltage and forward current ratings of the MBR0520LT1G are sufficient for your application. If you expect higher voltages or currents, consider using a diode with higher ratings.

Circuit Redesign: If overvoltage or overcurrent is an ongoing issue, you may need to redesign the circuit to better regulate power or prevent spikes from reaching the diode. Consider adding resistors or using a more robust diode that can handle larger amounts of power.

2.2 Solution for Thermal Overload

Excessive heating is a common issue with Schottky diodes, especially in high-power applications. Here’s how to deal with it:

Improve Heat Dissipation: Ensure that your circuit has adequate heat sinking and airflow to dissipate the heat generated by the diode. Adding a heatsink to the diode package or placing it in an area with better airflow can significantly reduce the risk of overheating.

Use a Lower Forward Current: If possible, reduce the forward current passing through the diode. Using the MBR0520LT1G in circuits with lower currents will keep the diode cooler and reduce the likelihood of thermal failure.

Check the PCB Design: Ensure that the diode is properly soldered and that the PCB design allows for efficient heat transfer. If necessary, reflow soldering or using a larger trace to distribute heat more evenly can help.

2.3 Solution for Incorrect Polarity

If incorrect polarity is causing your MBR0520LT1G to fail, the solution is simple:

Double-check Orientation: Always ensure that the diode is installed in the correct direction. The cathode (marked with a stripe) should be connected to the more positive side of the circuit, while the anode should face the negative side.

Use Diode Protection Circuits: In sensitive circuits, consider adding reverse polarity protection using a second diode or other protective components. This will prevent damage from accidentally reversing the polarity of the MBR0520LT1G.

2.4 Solution for Electrostatic Discharge (ESD)

To protect the MBR0520LT1G from ESD-related failures:

Handle Components Properly: Always follow ESD safety guidelines when handling the diode. Use grounded wrist straps and work in ESD-protected environments to prevent electrostatic buildup.

Use ESD Protection Devices: Install ESD protection diodes or transient voltage suppressors in your circuit, especially if the MBR0520LT1G is exposed to environments with high static electricity risks.

2.5 Solution for Aging or Mechanical Damage

If aging or mechanical damage is the cause of the diode’s failure, you may need to replace the part. However, there are ways to extend the life of the MBR0520LT1G:

Choose Quality Components: Always choose high-quality diodes from reputable suppliers. Cheap or counterfeit parts may not perform well over time.

Avoid Physical Stress: During the assembly process, be cautious of mechanical stress on the diode. Ensure that it is not subjected to excessive force during soldering or in the final product.

Use Proper Mounting: If the diode is mounted on a PCB, ensure it is securely attached to avoid vibration or movement that could damage the leads.

2.6 Preventative Maintenance for Long-term Reliability

To ensure long-term reliability of the MBR0520LT1G, consider the following preventative measures:

Monitor Circuit Health: Regularly monitor the circuit for abnormal heating, voltage drops, or other signs of stress. Early detection of issues can prevent catastrophic failures.

Regular Testing: Periodically test the diode’s functionality using the methods outlined above. This will help you catch potential issues before they lead to failure.

Use Protective Circuitry: Implementing design features such as voltage clamping, overcurrent protection, and thermal monitoring will go a long way in preventing damage to the diode and improving the overall lifespan of the circuit.

Conclusion

The MBR0520LT1G is a versatile and reliable Schottky diode, but like all electronic components, it can encounter issues due to improper handling, environmental factors, or circuit design flaws. By understanding common failure modes, testing methods, and solutions, you can keep your circuits running smoothly and avoid unnecessary downtime or component replacement. Proper preventative measures, along with careful circuit design and maintenance, can ensure the longevity and performance of your MBR0520LT1G diode for years to come.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.