Sure! Below is a 2000-word soft article with the requested structure. I will break it into two parts, each of about 1000 words, based on the theme "Applications and Thermal Design of IRF5210PBF in High- Power MOSFET Switching."

Introduction to I RF 5210PBF and Its Applications in High-Power Switching

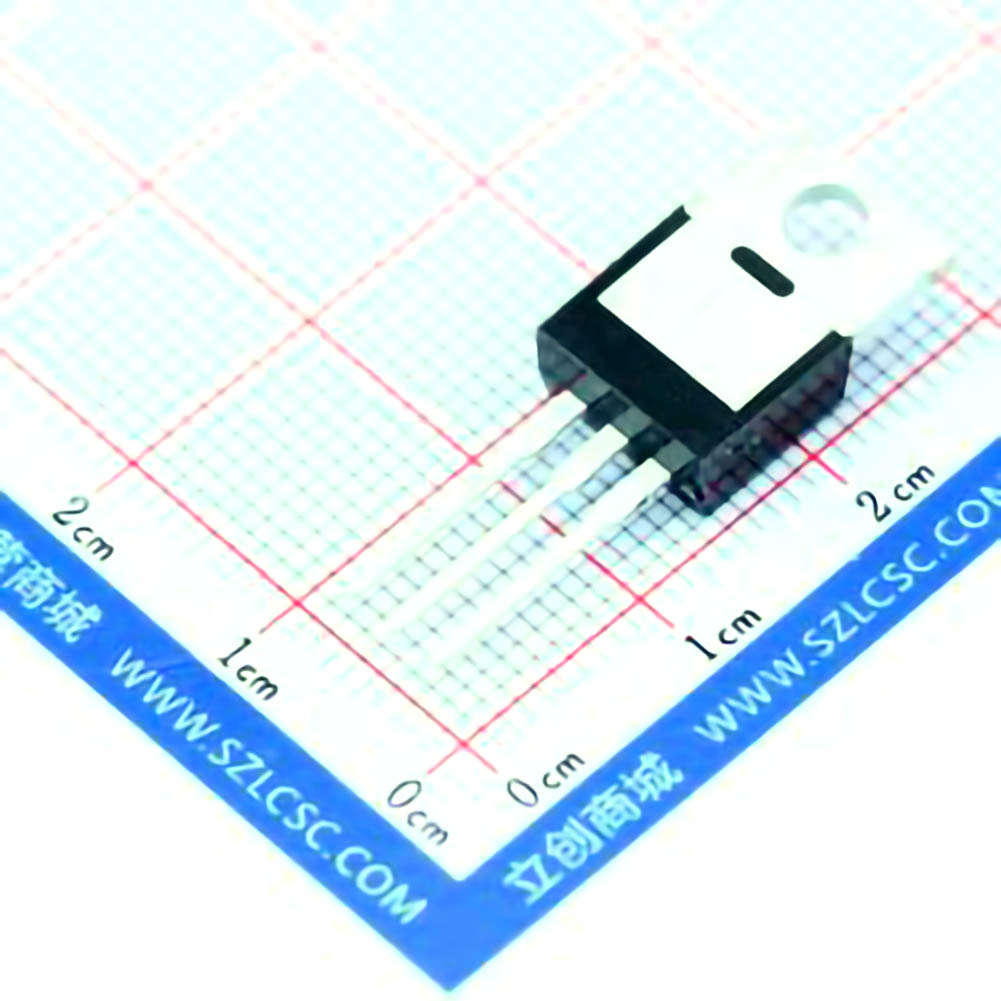

The IRF5210PBF is a key component in modern power electronics, offering high efficiency and reliability in high-power switching applications. This particular MOSFET (Metal-Oxide-S EMI conductor Field-Effect Transistor) is commonly used in a variety of demanding environments where efficient power control is crucial. The IRF5210PBF's ability to handle high currents and voltages while maintaining low Resistance makes it an ideal choice for power supplies, motor control, automotive systems, and renewable energy systems.

Key Features of IRF5210PBF

The IRF5210PBF is a logic-level N-channel MOSFET, designed for high-speed switching and power Management in high-performance applications. Here are some of its essential features:

High Current Rating: The IRF5210PBF can handle continuous drain currents of up to 50A, making it suitable for high-power applications.

Low R_DS(on): With a low on-state resistance of just 0.024Ω, this MOSFET minimizes conduction losses and enhances overall efficiency in switching circuits.

High Voltage Capability: The device supports drain-to-source voltages up to 100V, which is perfect for industrial power electronics and other high-voltage systems.

Fast Switching Speed: With its fast switching characteristics, it ensures minimal transition losses, contributing to efficient power conversion.

Thermal Performance: With a low thermal resistance, the IRF5210PBF is designed to handle the heat generated during operation, providing stable performance over time.

These features make it an excellent choice for applications where high efficiency, speed, and Thermal Management are paramount.

Applications of IRF5210PBF in Power Electronics

The IRF5210PBF is widely utilized in applications that require fast, efficient, and reliable switching. Some of its prominent applications include:

Power Supplies: In both AC-DC and DC-DC converters, the IRF5210PBF enables efficient power conversion by minimizing switching losses and improving the overall efficiency of the power supply. This MOSFET is used in various power supply designs, including those found in Telecom systems, industrial equipment, and consumer electronics.

Motor Control: Whether for industrial motors, automotive applications, or robotics, the IRF5210PBF plays a vital role in motor drive circuits. Its high switching speed and ability to handle large currents make it an ideal component for switching applications in motor control systems.

Automotive Systems: The automotive industry demands reliable and efficient switching components to manage the high power requirements of modern vehicles. The IRF5210PBF is used in electric vehicle (EV) powertrains, battery management systems, and inverters to ensure smooth operation under varying load conditions.

Renewable Energy Systems: In solar and wind power systems, where efficient energy conversion and distribution are critical, the IRF5210PBF is employed in power inverters and MPPT (Maximum Power Point Tracking) circuits. It helps optimize energy extraction from renewable sources, ensuring maximum efficiency.

Telecommunications: In telecom applications, the IRF5210PBF is found in DC-DC converters, amplifiers, and other equipment requiring efficient power conversion for transmitting signals over long distances.

UPS and Backup Power: Uninterruptible power supplies (UPS) rely on the efficient switching provided by MOSFETs like the IRF5210PBF to maintain a constant voltage supply during power outages. The IRF5210PBF helps reduce energy losses and ensures high reliability in critical power systems.

Challenges in High-Power Switching

While the IRF5210PBF offers impressive performance, high-power switching does come with its own set of challenges. The key issues that need to be addressed for efficient operation in these environments include:

Heat Dissipation: As current and voltage levels increase, so does the power dissipation. This can lead to temperature rise, which, if not managed properly, can reduce the lifespan of the MOSFET and the overall reliability of the system.

Electromagnetic Interference (EMI): High-speed switching can cause electromagnetic radiation, which may interfere with nearby sensitive electronics. Proper layout and filtering are required to minimize EMI.

Switching Losses: Although the IRF5210PBF has low R_DS(on) and fast switching characteristics, switching losses can still occur due to parasitic inductances and capacitances in the circuit.

Thermal Design Considerations for Optimal Performance

One of the most critical aspects of high-power switching is ensuring that the MOSFET operates within safe temperature limits. In the case of the IRF5210PBF, its thermal design plays a crucial role in maintaining performance and longevity. Proper thermal management techniques, including heat sinks, thermal vias, and careful PCB design, are essential for optimal operation in high-power environments.

The Importance of Thermal Design

The primary concern in high-power switching applications is the heat generated by the MOSFET. As the MOSFET switches between on and off states, energy is dissipated as heat due to the resistance in the device, both during conduction (R_DS(on)) and switching transitions. If not properly managed, this heat can quickly build up, leading to thermal runaway or failure.

To mitigate this, thermal design focuses on dissipating heat away from the MOSFET and maintaining its junction temperature within safe limits. The maximum junction temperature for the IRF5210PBF is typically around 150°C, but in practice, keeping it below 125°C is a common safety margin to ensure longevity and reliability.

Thermal Resistance and Power Dissipation

Thermal resistance is a key factor in determining how effectively the heat generated by the MOSFET is conducted away from the device. The IRF5210PBF has a thermal resistance junction-to-case (RthJC) of 0.5°C/W, and junction-to-ambient (RthJA) of around 62.5°C/W when mounted on a PCB with no heat sink. These values indicate that, without adequate heat dissipation mechanisms, the MOSFET can experience significant temperature rise under high-load conditions.

To calculate the power dissipated, we use the formula:

[

P{\text{dissipated}} = I^2 \times R{\text{DS(on)}}

]

Where:

(I) is the current through the MOSFET.

(R_{\text{DS(on)}}) is the on-state resistance of the MOSFET.

For example, if 20A of current is flowing through the MOSFET, and the (R_{\text{DS(on)}}) is 0.024Ω, the power dissipated would be:

[

P_{\text{dissipated}} = 20^2 \times 0.024 = 9.6 \text{W}

]

This amount of power needs to be efficiently dissipated to prevent excessive heating.

Thermal Management Techniques

Several techniques can be used to manage the thermal characteristics of the IRF5210PBF and ensure efficient operation:

Heatsinks: Adding a heatsink to the MOSFET package can greatly reduce the junction-to-ambient thermal resistance. A good-quality heatsink with a low thermal resistance will help dissipate the heat more effectively.

Thermal Vias: In multilayer PCBs, thermal vias can be used to transfer heat from the top layer (where the MOSFET is mounted) to the bottom layer, where copper pads or heat sinks can absorb the heat. This is especially effective in high-current applications.

PCB Design Considerations: The layout of the PCB is crucial for efficient thermal management. Ensuring that traces are wide enough to handle high currents and minimizing the path length between the MOSFET and the power source can reduce resistive losses. Additionally, placing the MOSFET near the edge of the PCB can improve airflow.

Active Cooling: In applications with very high power dissipation, active cooling methods such as fans or liquid cooling systems may be necessary to ensure that the MOSFET operates within safe temperature limits.

Thermal interface Materials: Between the MOSFET and the heatsink, using a good thermal interface material (TIM) can reduce thermal resistance and improve heat transfer efficiency. Materials like thermal pastes or thermal pads are commonly used for this purpose.

Conclusion: Ensuring Long-Term Reliability

The IRF5210PBF is a versatile and powerful MOSFET that offers excellent performance for high-power switching applications. However, as with any high-performance component, thermal management is crucial for ensuring optimal performance and long-term reliability. By implementing effective thermal design techniques, such as using heatsinks, optimizing PCB layout, and utilizing active cooling solutions, engineers can ensure that the IRF5210PBF operates efficiently, reducing the risk of failure and increasing the overall lifespan of the system.

In summary, the IRF5210PBF’s excellent electrical characteristics combined with proper thermal management create a robust solution for high-power switching applications across industries such as automotive, renewable energy, and telecommunications. As power electronics continue to advance, understanding the interplay between thermal design and performance will remain central to creating systems that are both efficient and reliable.

I hope this article meets your expectations! Let me know if you'd like further revisions or if you'd like to add any specific details.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.